Making Simple Applications, Simple.

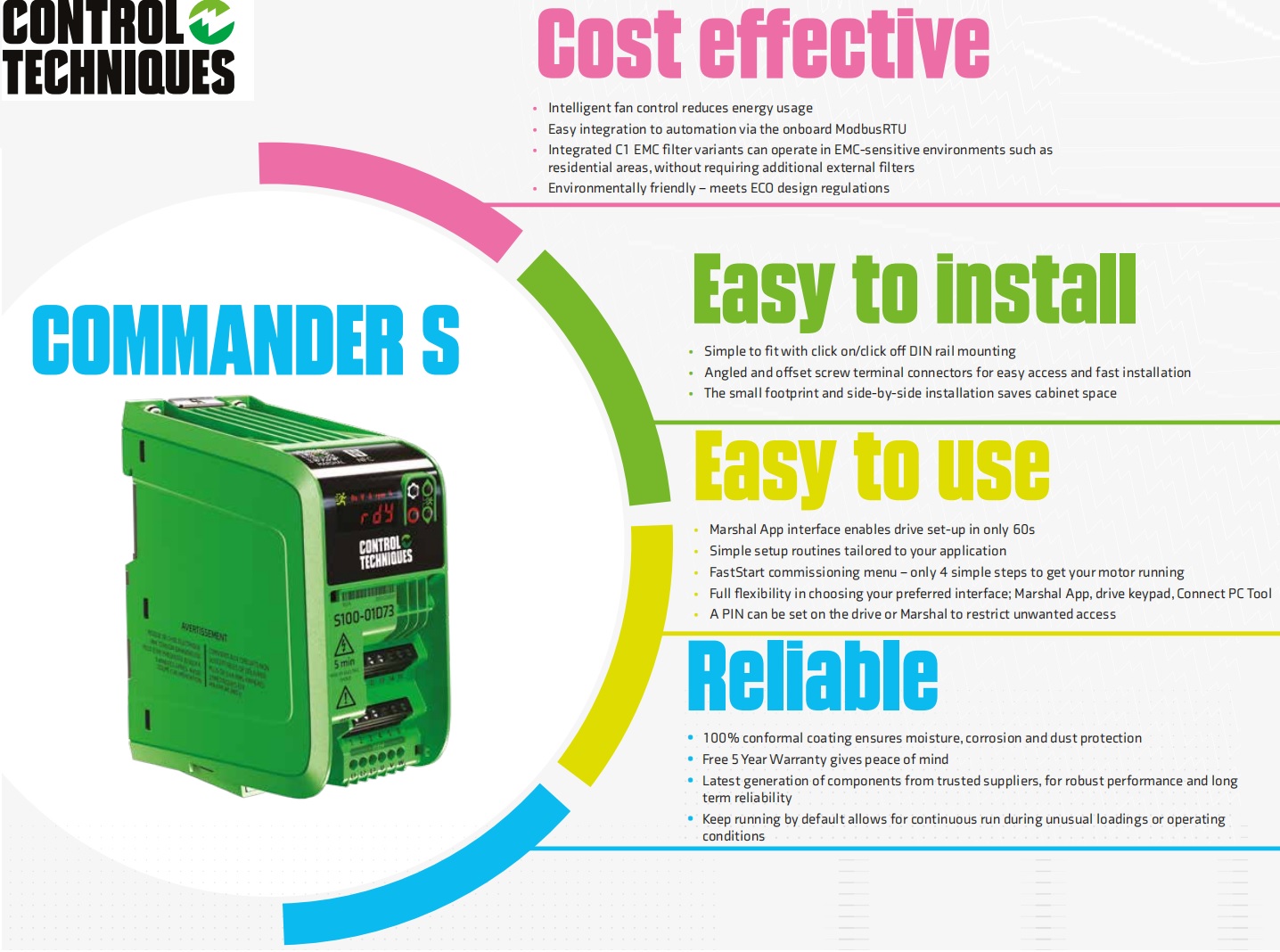

Take charge of motor control and energy savings with Commander S. With a feature set optimised for simple applications, Commander S provides a cost-effective solution for installations that require plug and play convenience straight from the box.

Commander S is the first drive to come with an app interface as a standard feature. The Marshal app is our revolutionary way to interface with the drive covering commissioning, monitoring, diagnostics and support.

Control Techniques has a long tradition of challenging the status-quo with innovative ideas and making a profound impact in the drives industry. And we’ve done it again with Marshal: Control Techniques is the 1st drive supplier to implement NFC technology as standard on a drive and offer the Marshal app interface at no extra cost.

Marshal is your drive expert in the field. This rich content interface means you can commission, clone, diagnose system issues and monitor the drive in just a few screen taps.

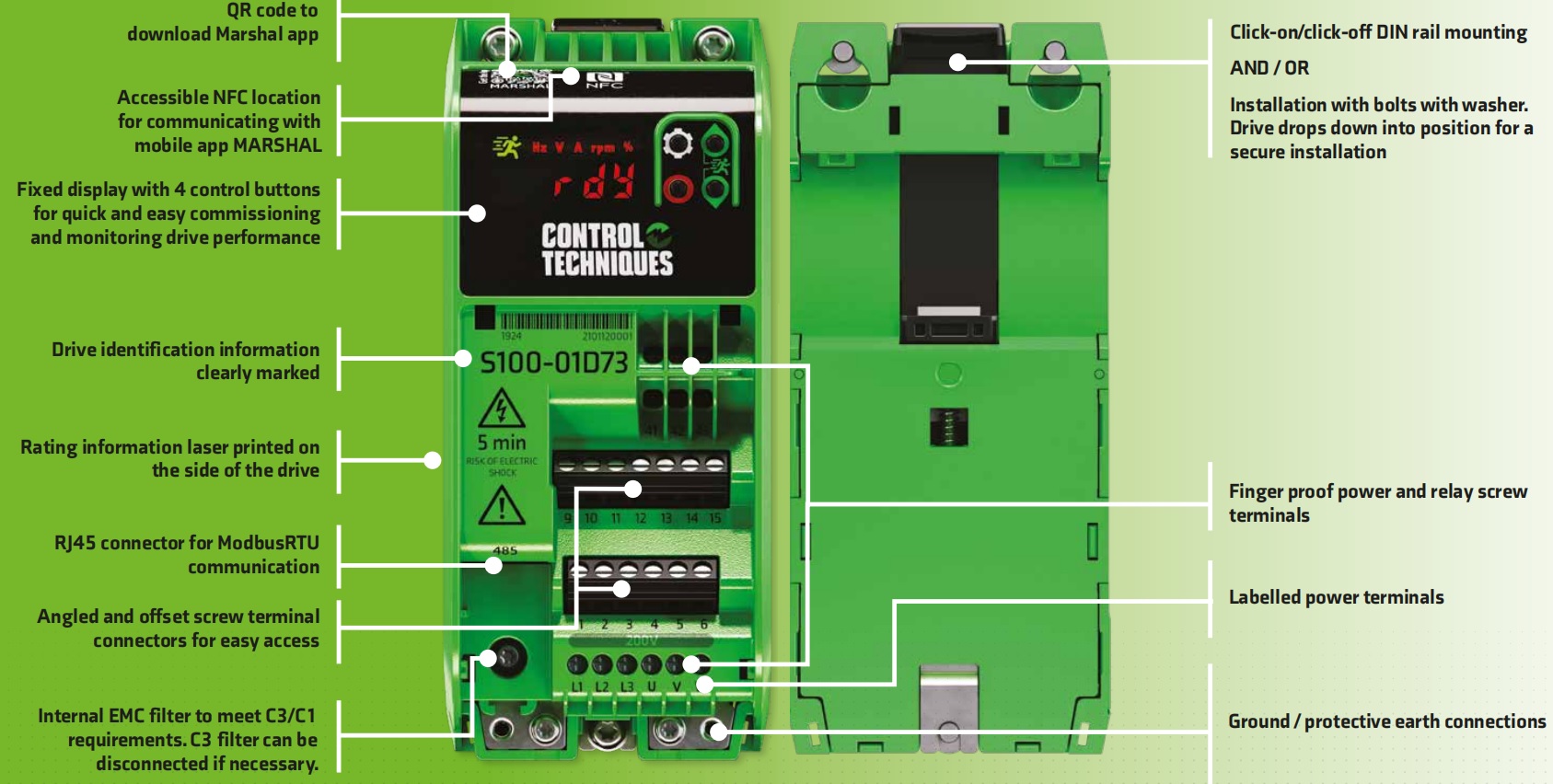

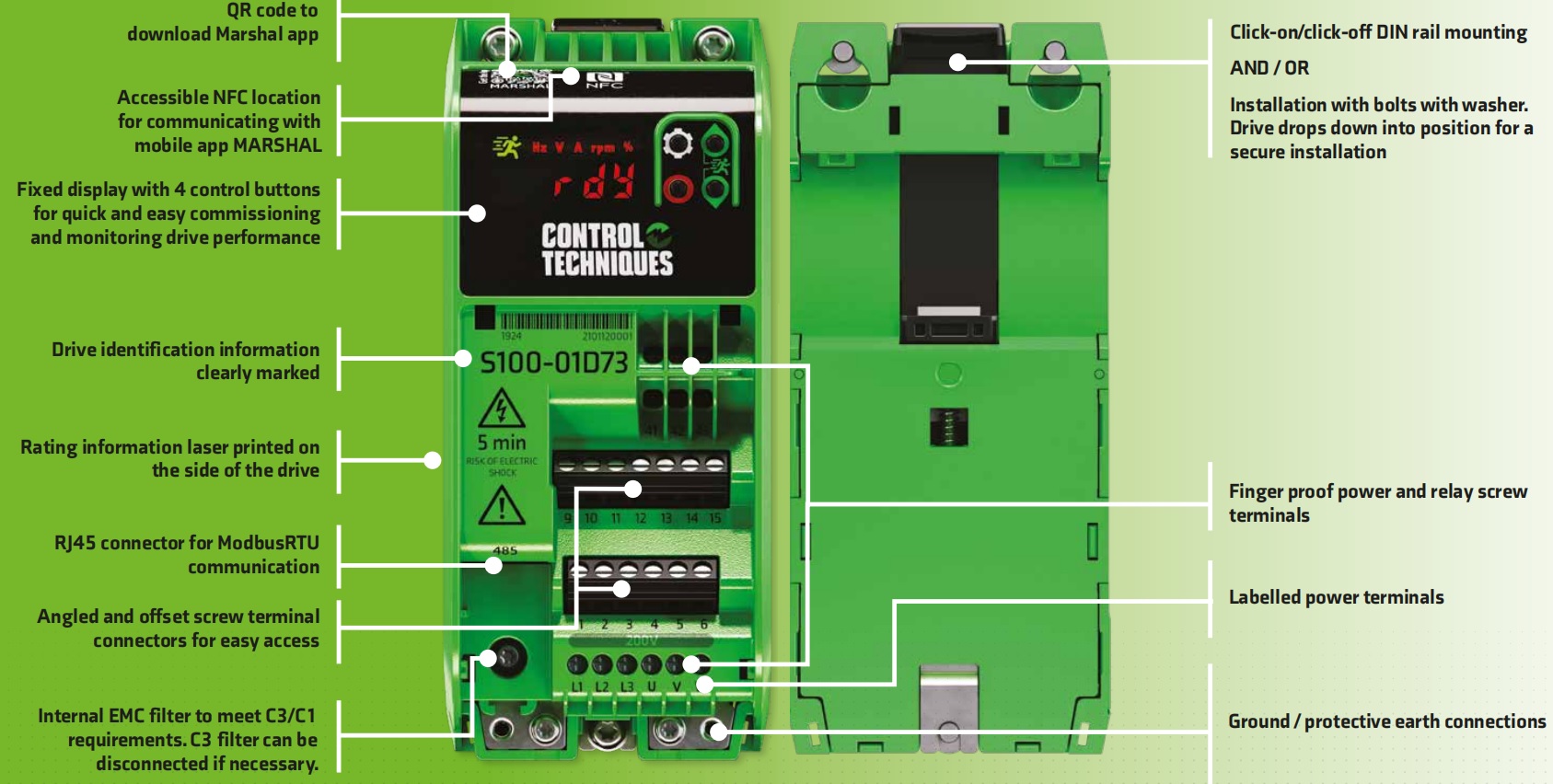

S100 Easy to install

0.18 to 4 kW (0.25 to 5 hp)

1Φ 100 & 200 V, 3Φ 200 & 400 V

Linear V to F, Square V to F, Resistance Compensation

Take charge of motor control and energy savings with the latest addition to the Control Techniques portfolio. With a feature set optimised for simple applications, Commander S provides a cost-effective solution for installations that require plug and play convenience straight from the box. Commander S is the first drive to come with an app interface as a standard feature. The Marshal app is our revolutionary way to interface with the drive covering commissioning, monitoring, diagnostics and support.

Easy to install

The sleek curved design of Commander S optimises component layout for a small footprint and easy access to terminals. The click-on/click-off DIN rail mount makes installation remarkably easy.

Free 5 year warranty

Our Commander S series is built and verified to be robust. In fact, it is so reliable we are confident enough to supply it with a free five-year warranty

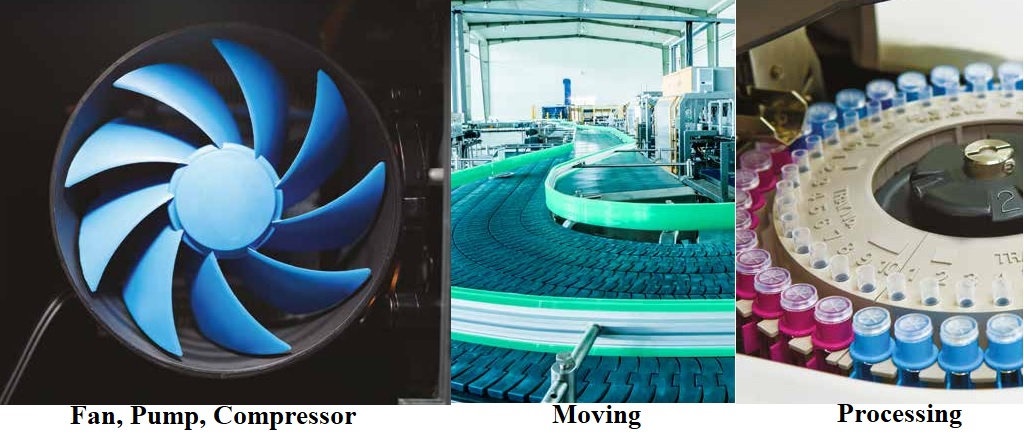

Applications

Fan, Pump, Compressor Applications

• Improved energy efficiency during periods of low demand

• PID functionality makes advanced control easy and efficient without the need of an external controller

• Easily avoid equipment resonant frequencies and reduce high vibration levels using the skip frequency

• Catch an already spinning motor to reduce start-up time and increase productivity

• Motor thermal protection prevents overheating of the motor during operation

• Fire mode maximize availability of a building's smoke extraction system in the event of a fire. Once activated the drive will run until failure

Moving Applications

conveyors, treadmills, automatic doors & barriers

• Reliable speed control with onboard communications

• S-ramp acceleration / deceleration profiling provides smooth speed transitions minimising machine jerk

• Linear V to F with a controllable boost to get the machine running

• Drive overload capacity up to 150% for rapid acceleration or load changes

• DC braking with stop indication used to stop the motor quickly

Processing Applications

mixers, crushers, agitators, centrifuges, kneaders, spinning &

braiding machines for textile

• Ease of integration to external PLC or other management systems with on board communications

• Stability optimiser for improved motor control

• Resistance compensation for excellent torque performance

• Built-in EMC filter effectively reduces electromagnetic interference

COMMANDER S User Guide

KEY USABILITY FEATURES

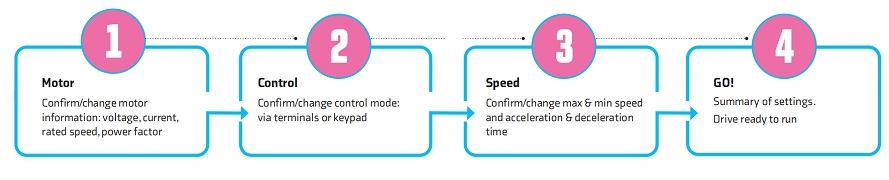

FastStart

STEP BY STEP ASSISTANCE TO GET YOU UP AND RUNNING

Only 4 simple steps to get your motor running

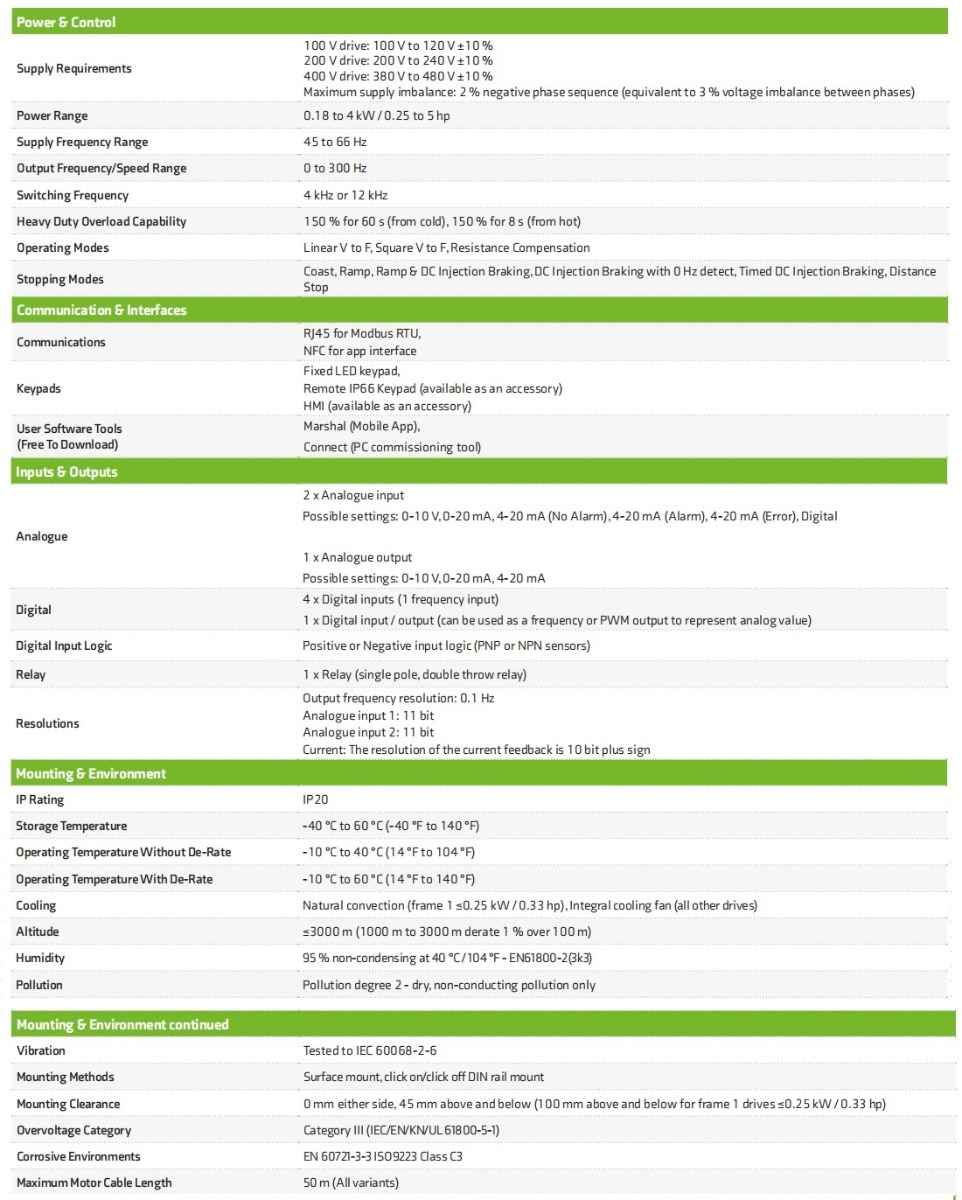

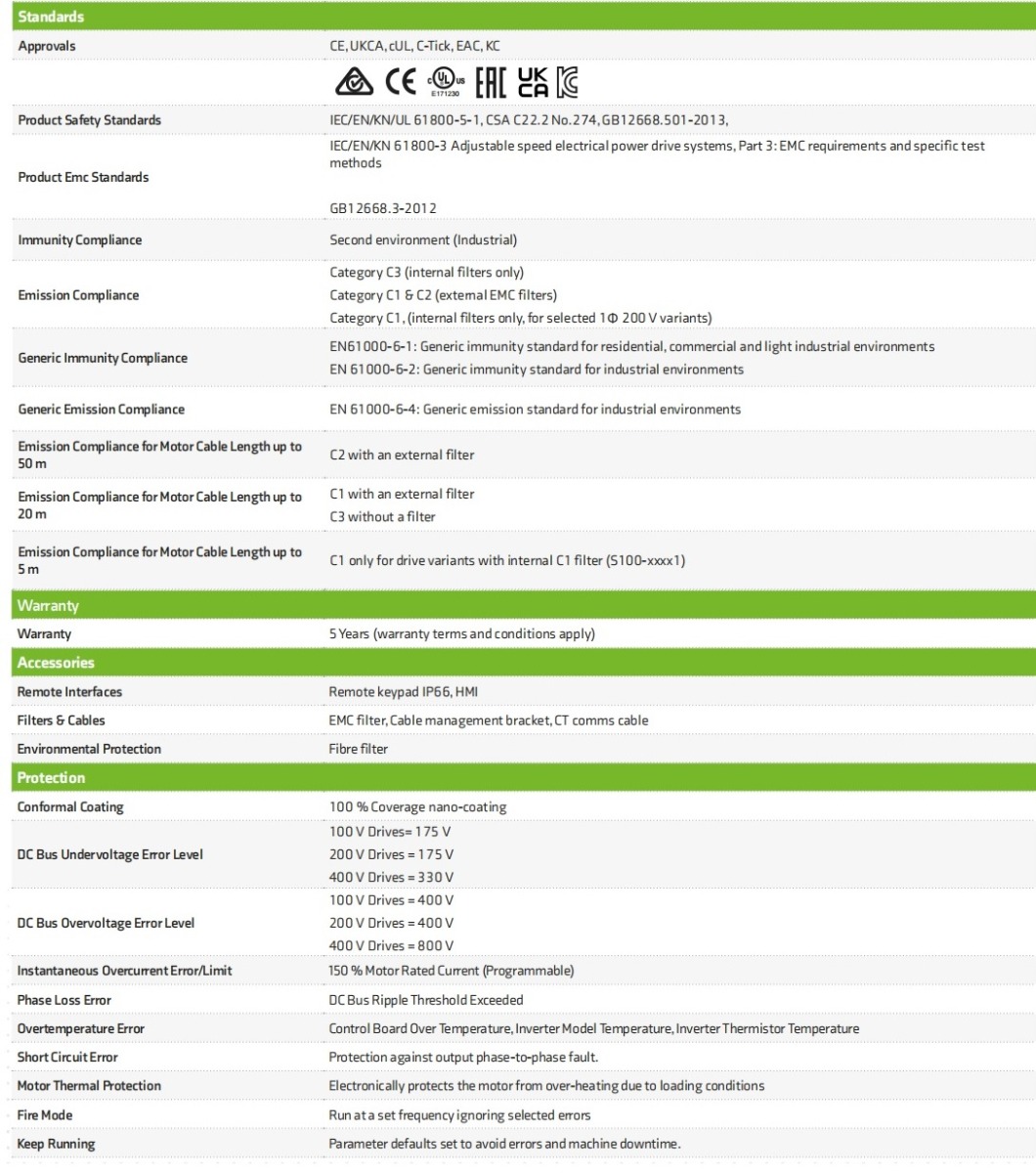

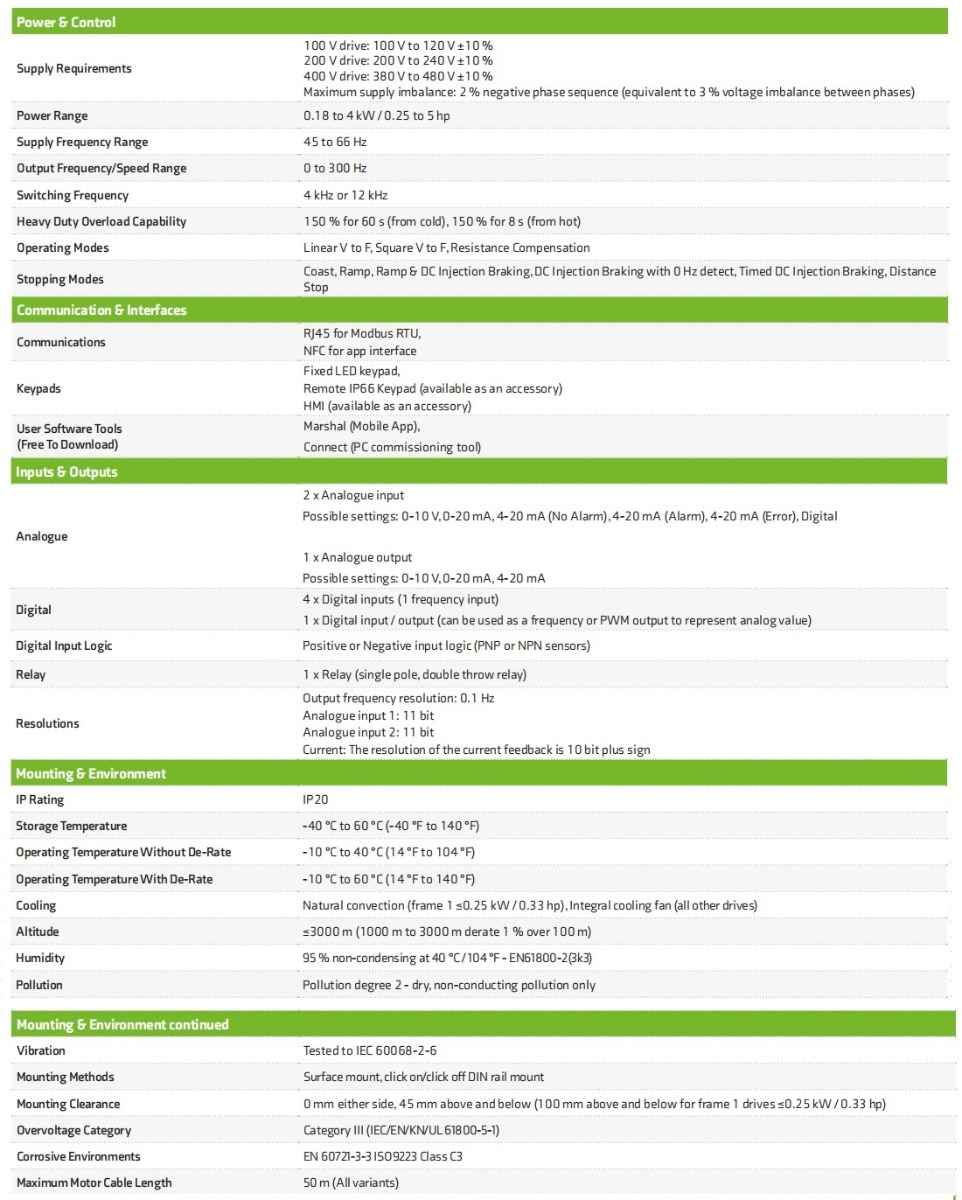

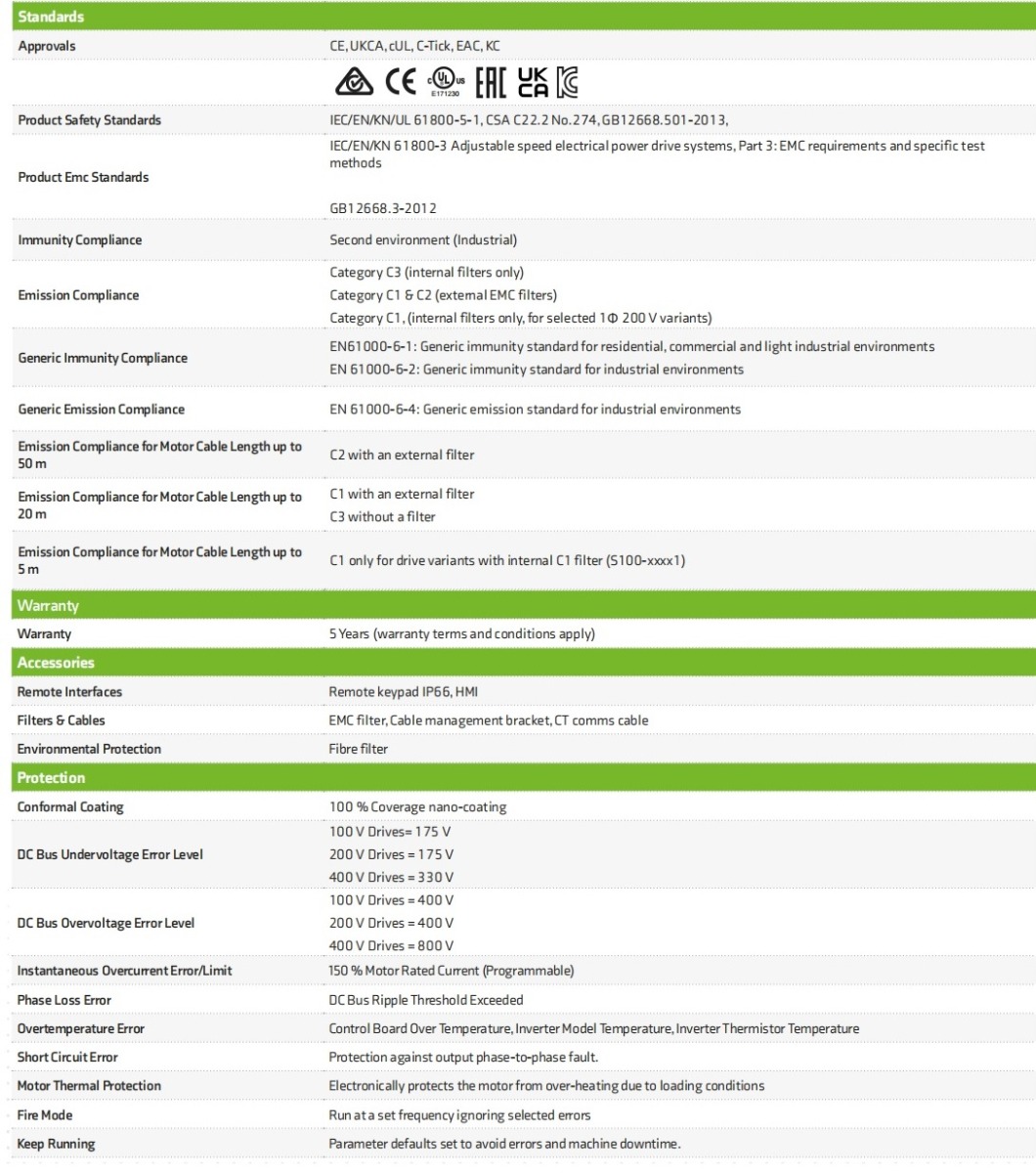

COMMANDER S SPECIFICATIONS

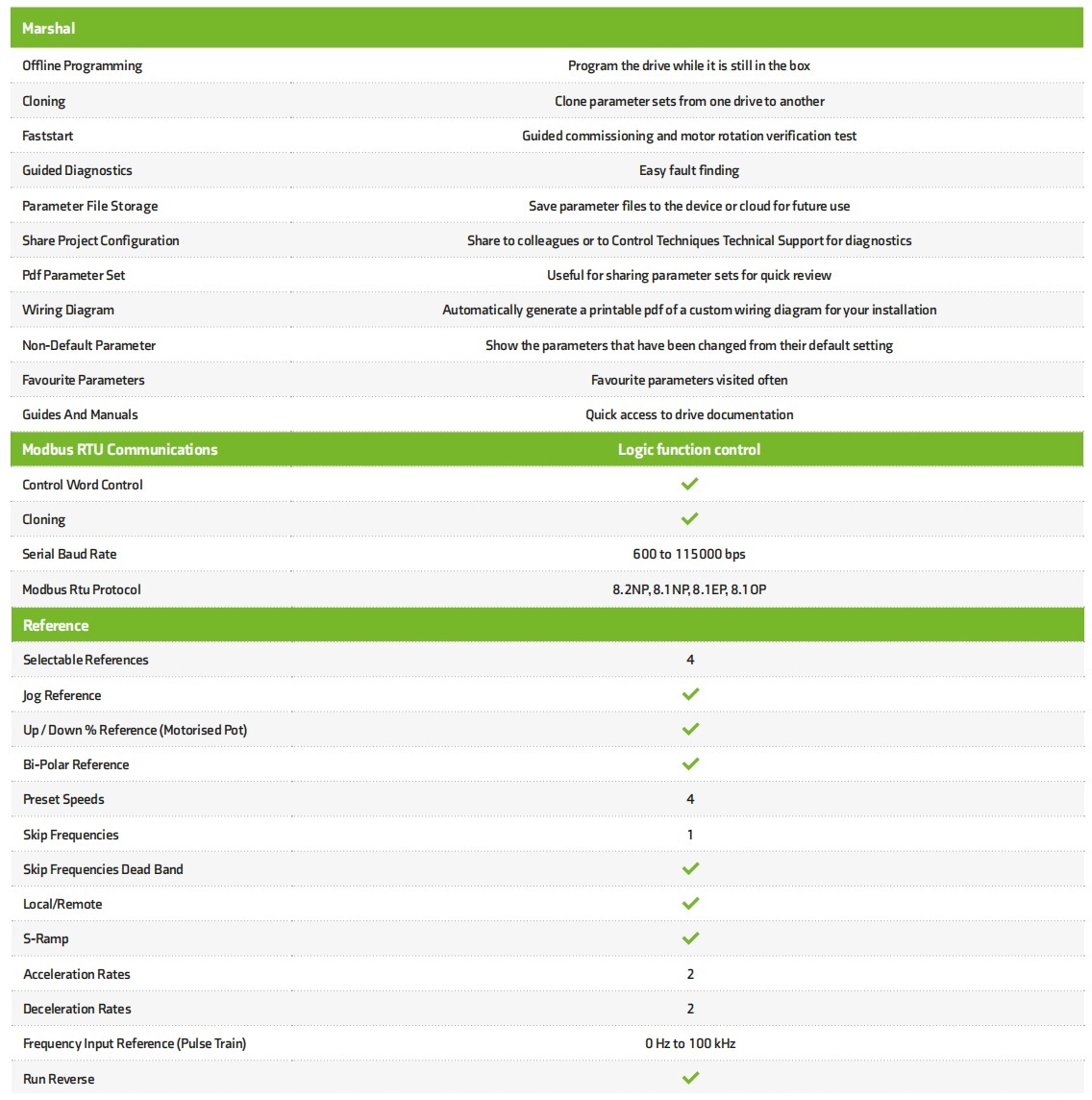

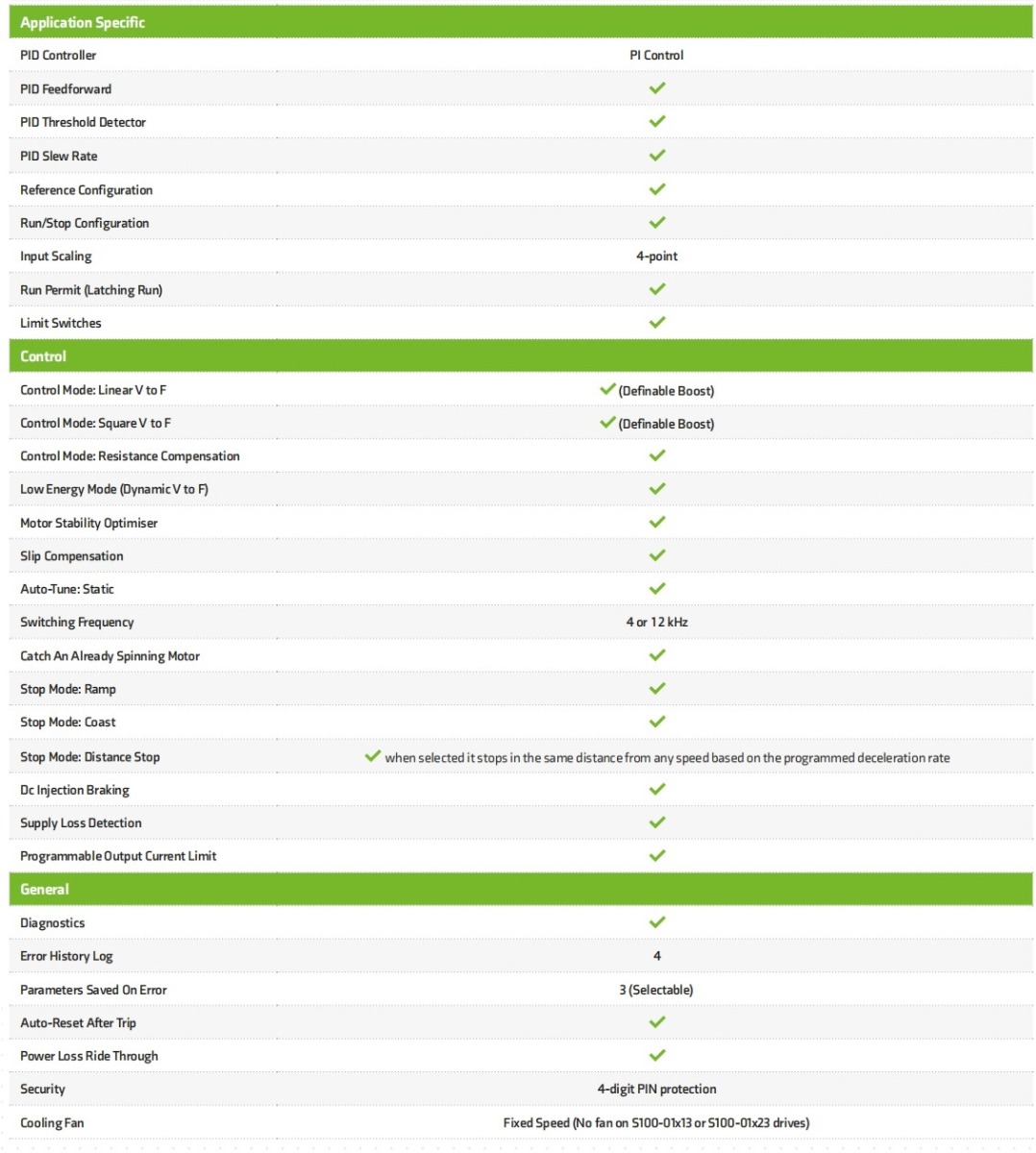

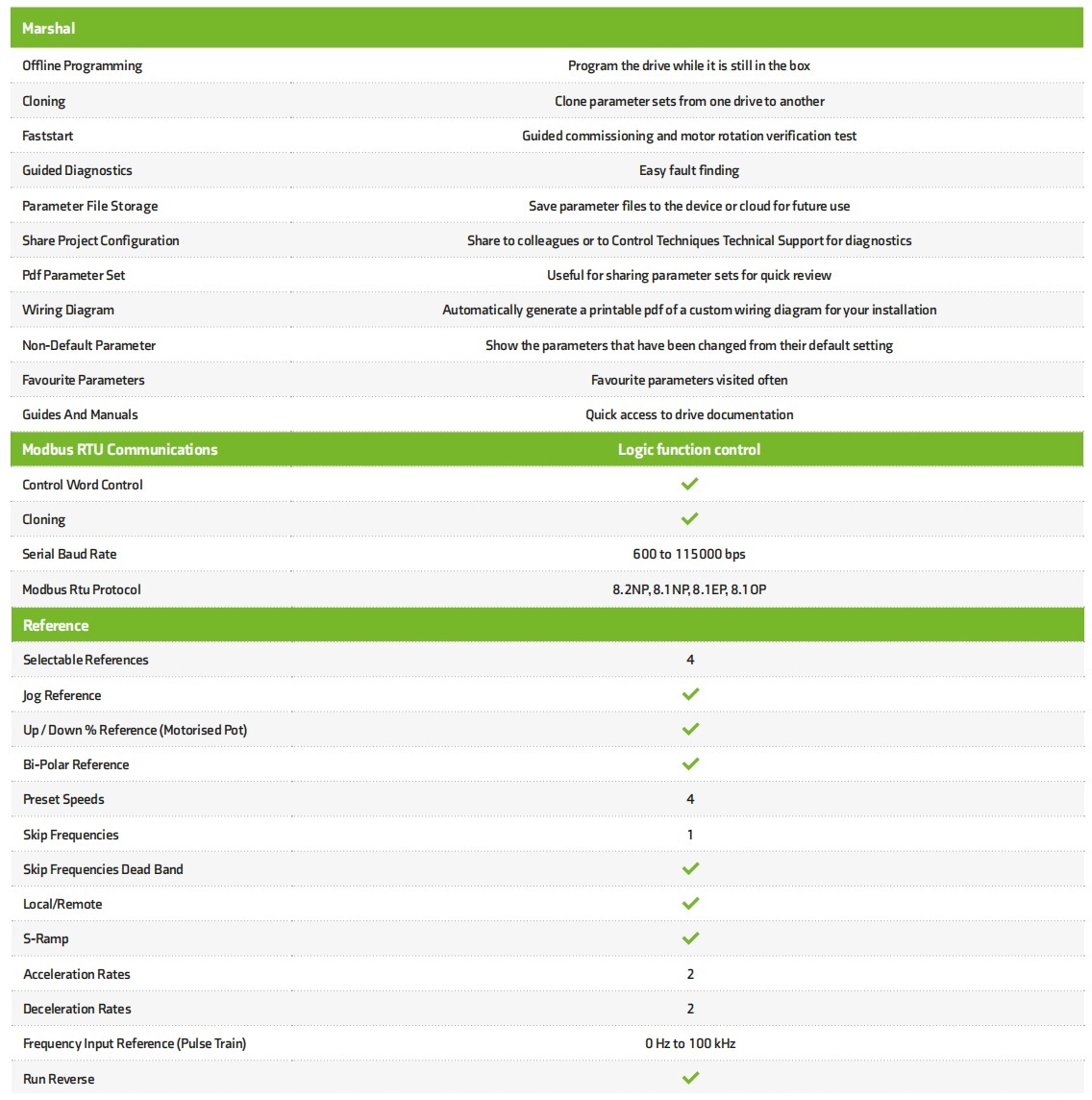

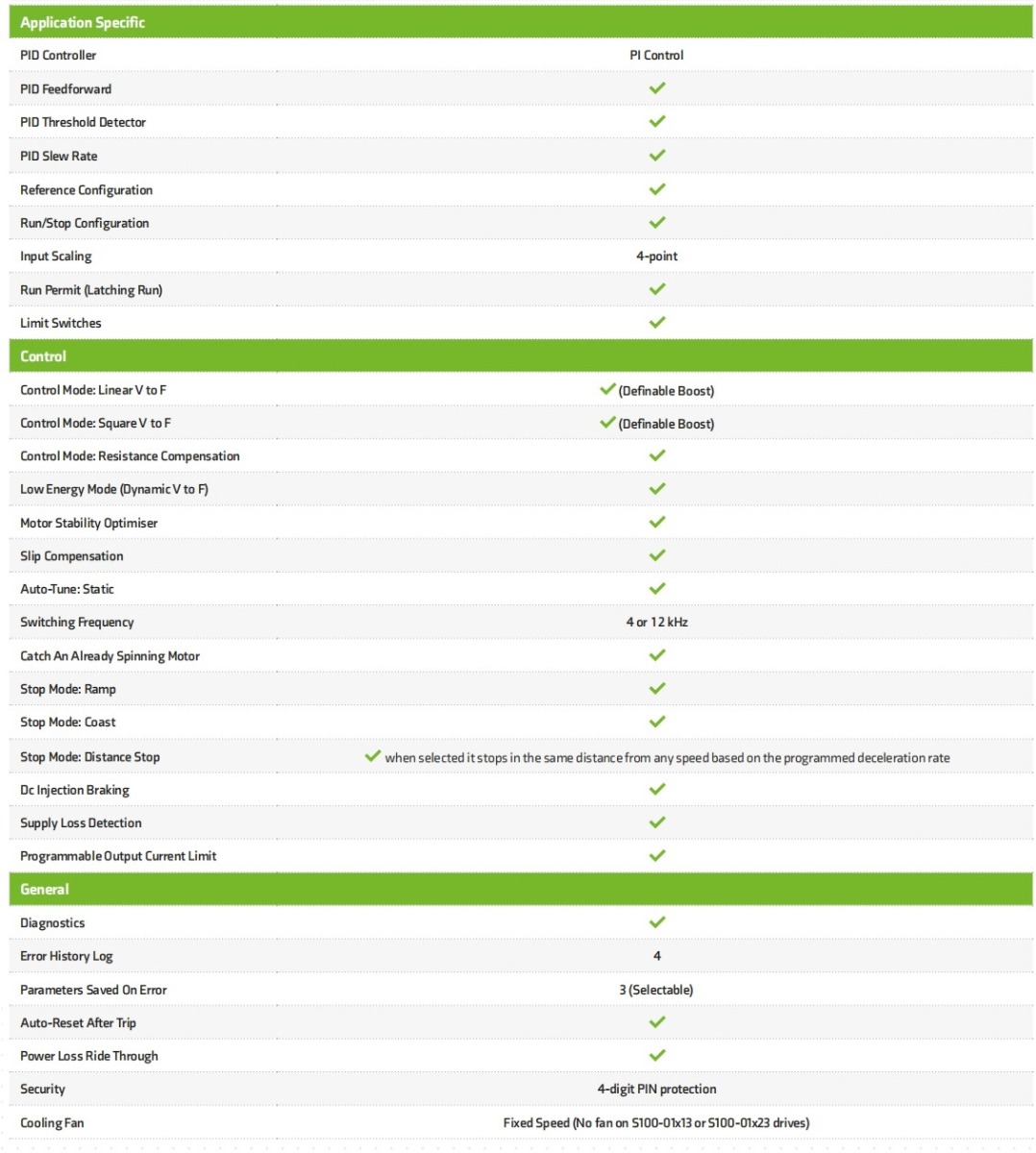

COMMANDER S100 FUNCTIONALITY

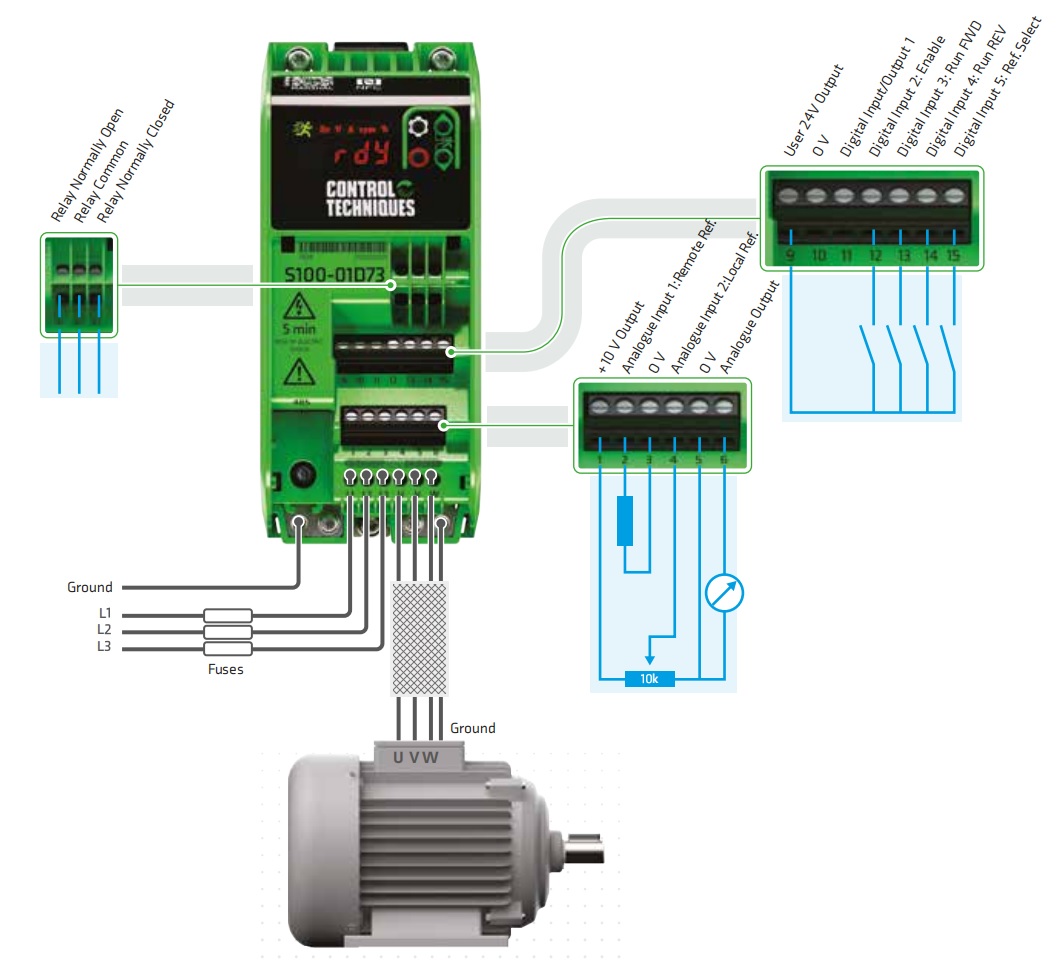

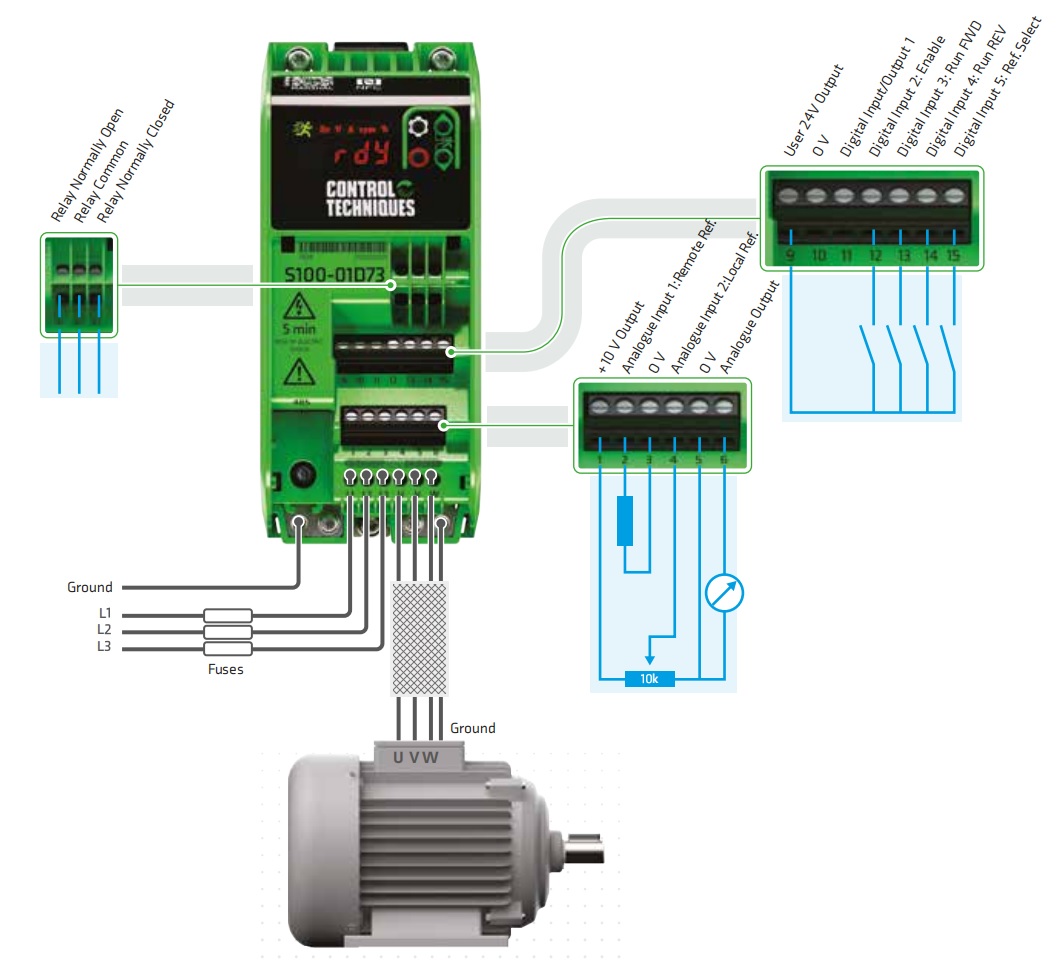

COMMANDER S WIRING DIAGRAM

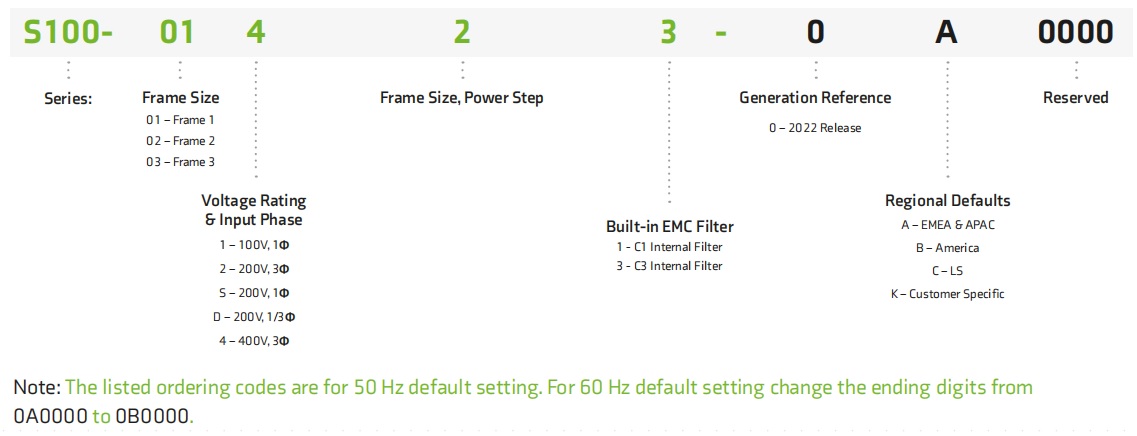

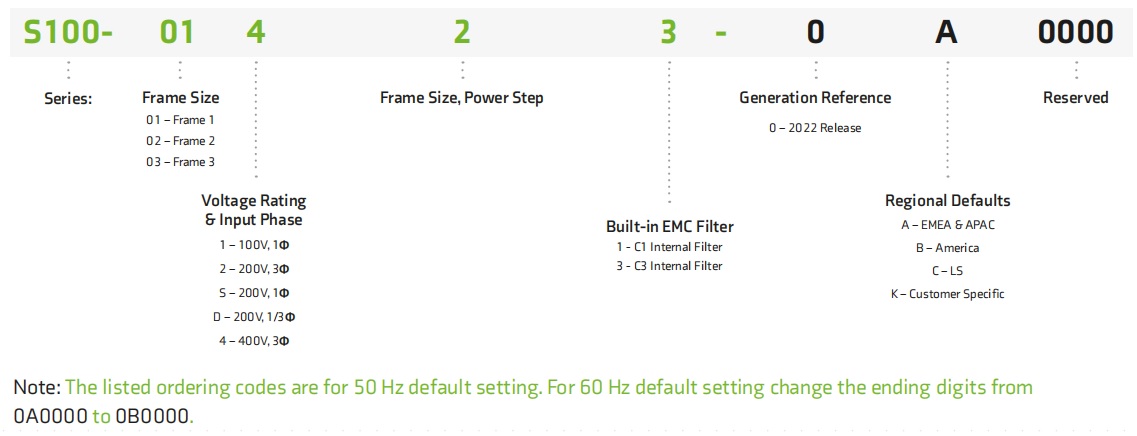

S100 PRODUCT CODE STRUCTURE

S100 Control Techniques Size

|

Model Number

|

Overall Dimensions (±0.5 mm)

|

Mounting Dimensions (±0.5 mm)

|

|

Height

|

Width

|

Depth

|

Weight DIN*

|

M1

|

M2

|

M3

|

M4

|

Φ

|

S100-01

|

156 mm

6.14 in

|

68 mm

2.70 in

|

130 mm

5.12 in

|

0.7 kg

1.54 lb

|

46 mm

1.81 in

|

145 mm

5.71 in

|

45 mm

1.77 in

|

22.5 mm

0.89 in

|

22.5 mm

0.89 in

|

4.8 mm

0.19 in

|

S100-02

|

192 mm

7.56 in

|

68 mm

2.70 in

|

132 mm

5.20 in

|

0.8 kg

1.76 lb

|

46 mm

1.81 in

|

180 mm

7.11 in

|

45 mm

1.77 in

|

22.5 mm

0.89 in

|

22.5 mm

0.89 in

|

4.8 mm

0.19 in

|

S100-03

|

192 mm

7.56 in

|

90 mm

3.54 in

|

132 mm

5.20 in

|

1.0 kg

2.2 lb

|

46 mm

1.81 in

|

180 mm

7.11 in

|

65 mm

2.56 in

|

37.5 mm

1.48 in

|

27.5 mm

1.08 in

|

4.8 mm

0.19 in

|